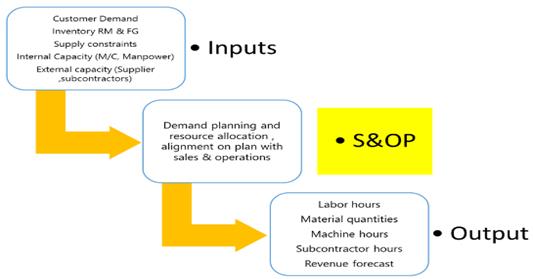

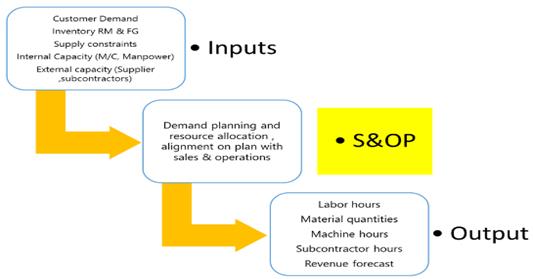

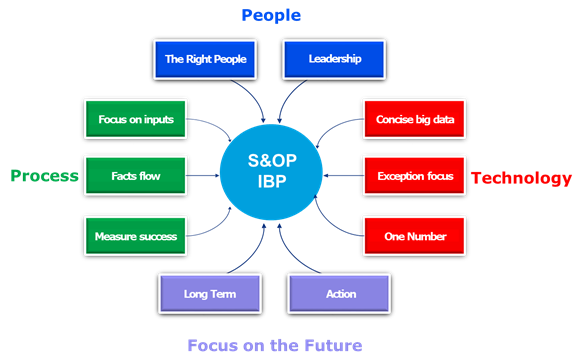

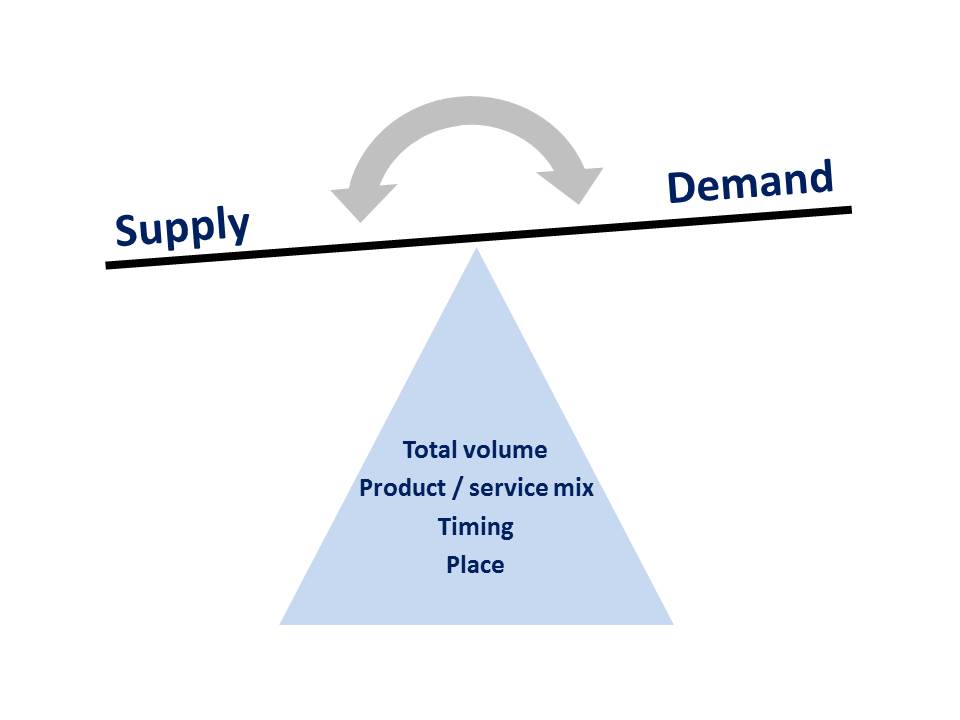

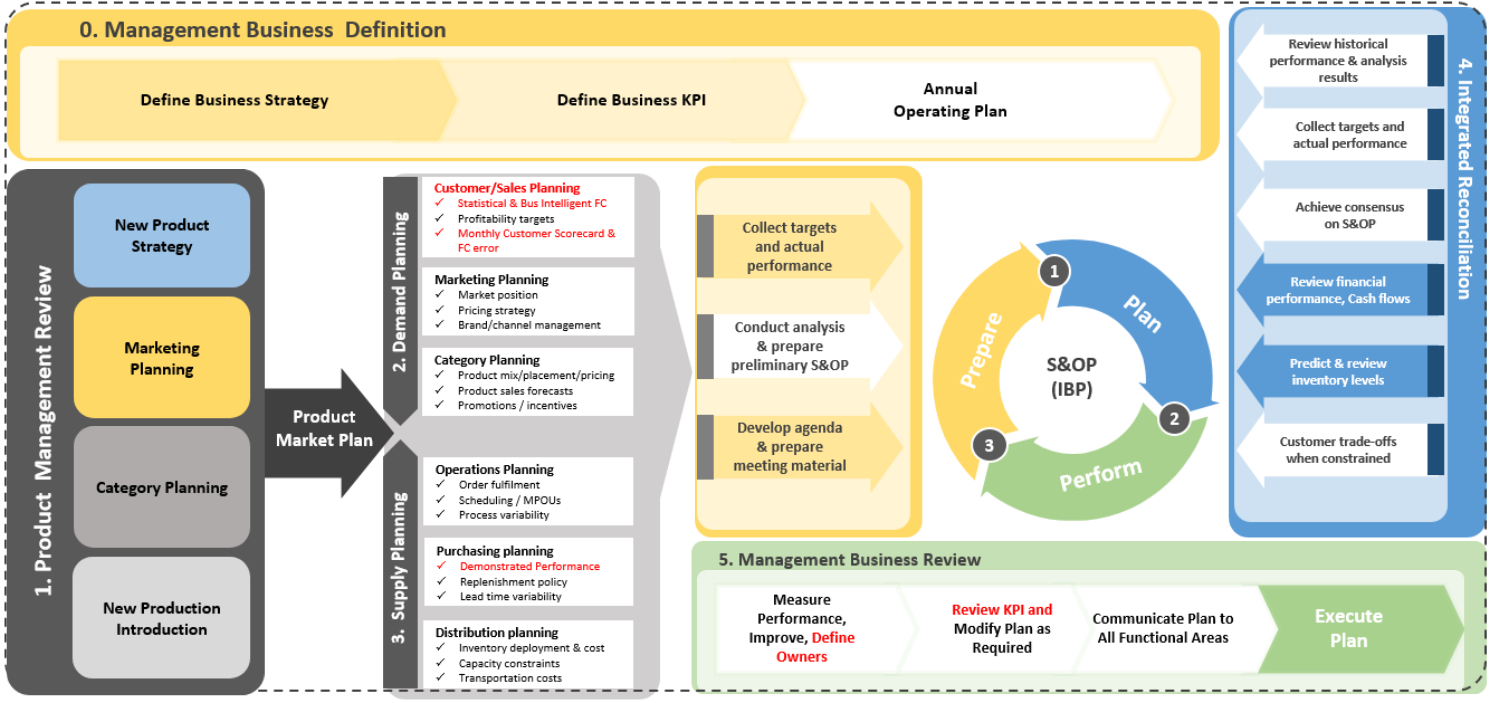

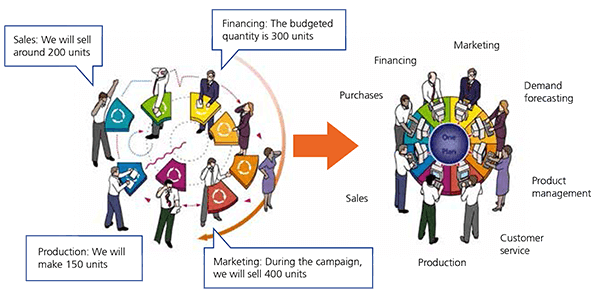

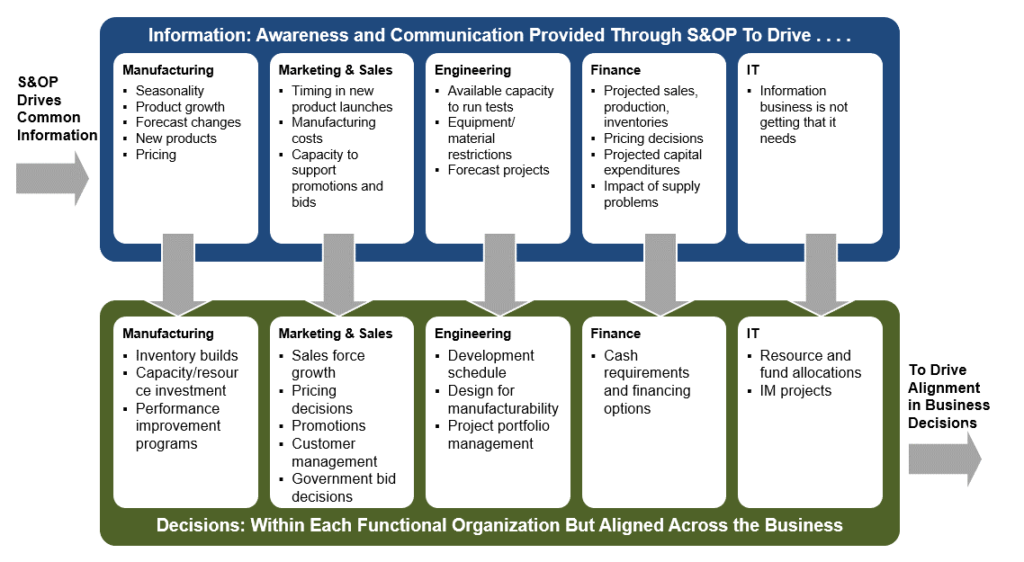

S&OP, or sales & operations planning, is a monthly integrated business management process that empowers leadership to focus on key supply chain drivers, including sales, marketing, demand management, production, inventory management, and new product introduction With an eye on financial and business impact, the goal of S&OP software is to Sales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity)Organizations without S&OP may "unconsciously" attempt to establish equilibrium between demand and supply However, S&OP demands a formal and rigorous process An effective, longterm S&OP process needs a strong foundation and requires the following to be established

S And Op Process Tutorial

S&op planning process

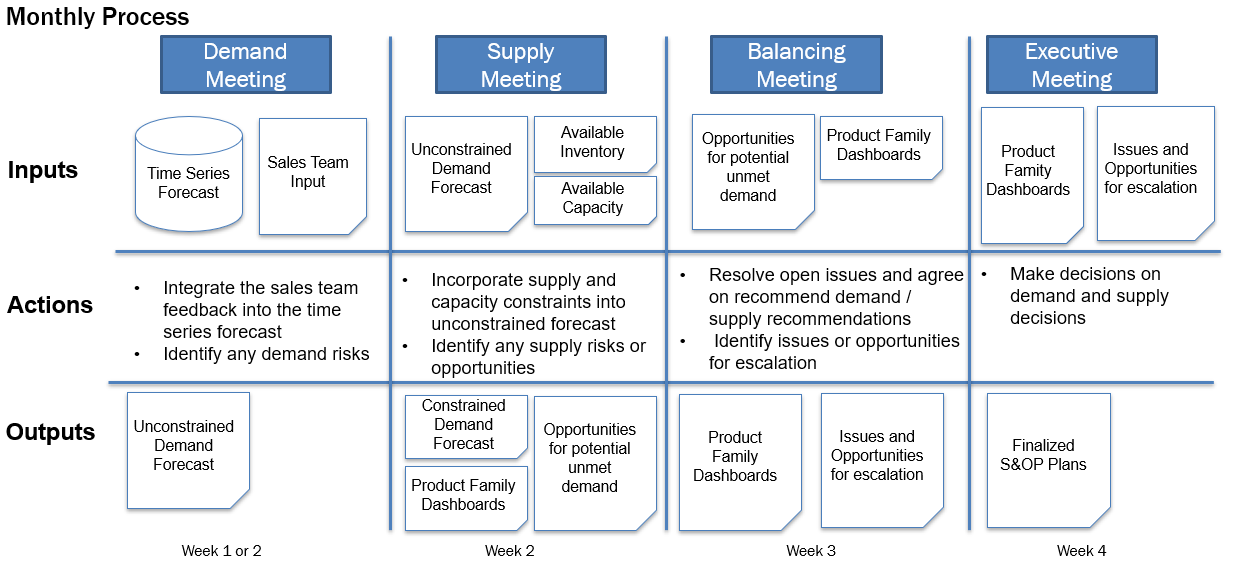

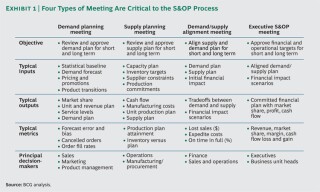

S&op planning process-S&OP, or sales and operations planning, is an integrated business management process that drives organizational consensus to balance supply and demand The S&OP process, which typically happens monthly, aligns operational areas – such as sales, marketing, product development, manufacturing, procurement, finance, and accounting – so theyS&OP stands for sales and operation plan and sales and operations planning at the same time It is both a plan and the process that creates, implements, monitors, and continuously improves the plan The S&OP process involves a series of meetings to meet a consensus A demand and production plans that reflect the results of demandside sensing

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

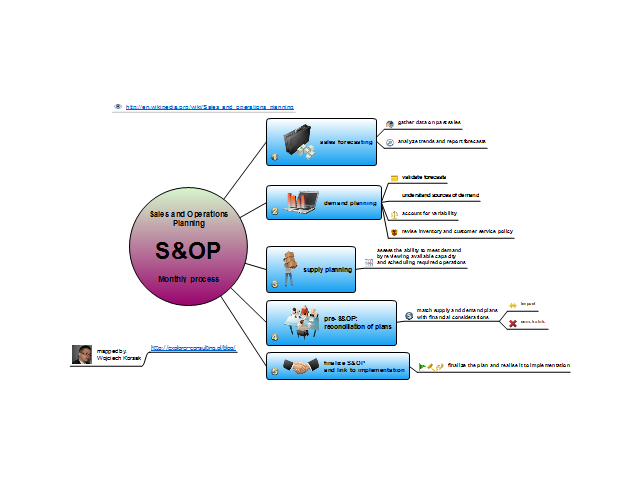

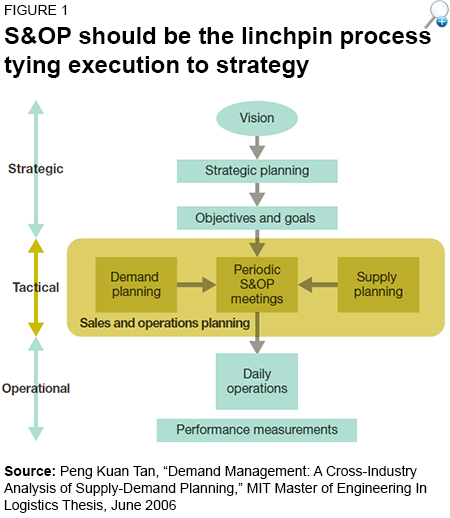

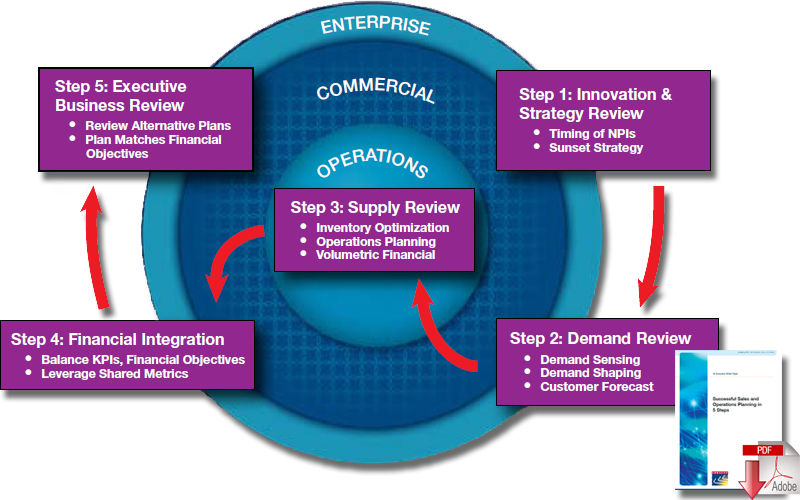

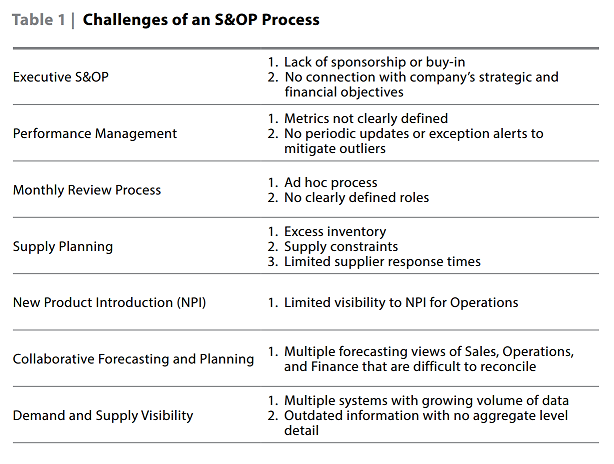

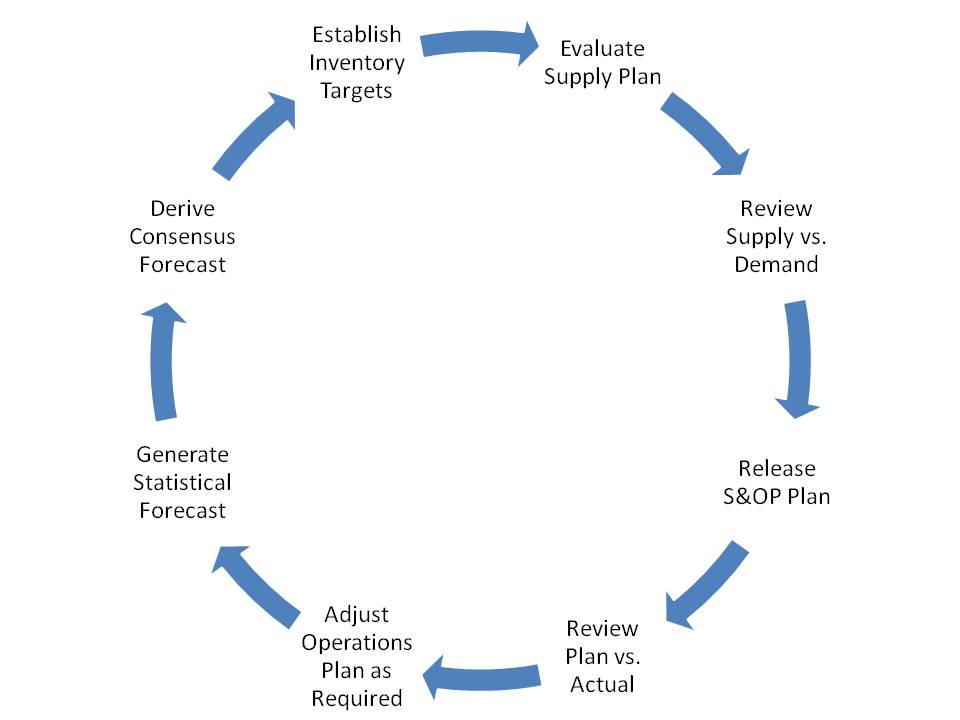

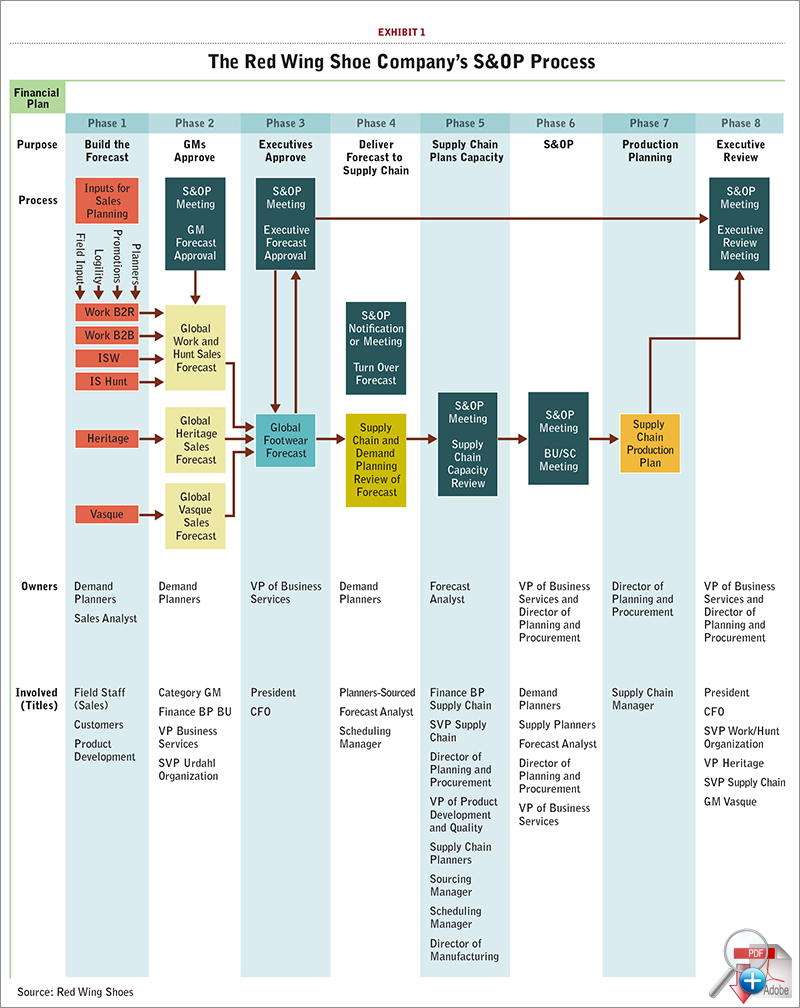

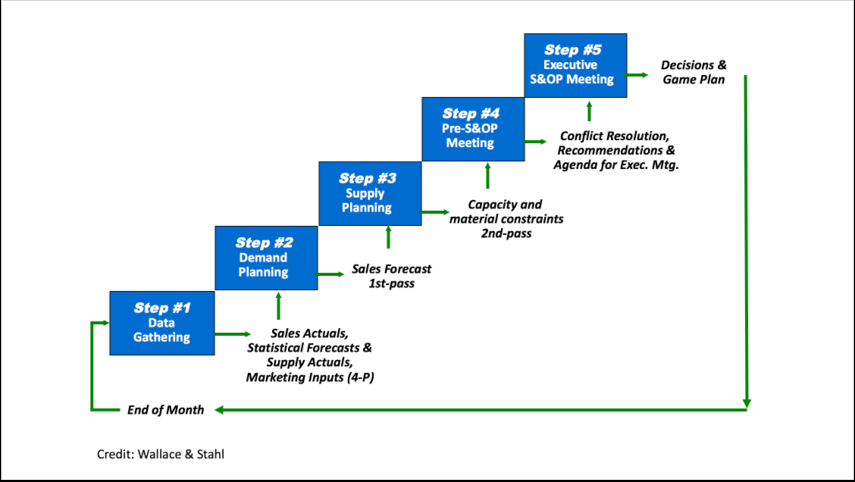

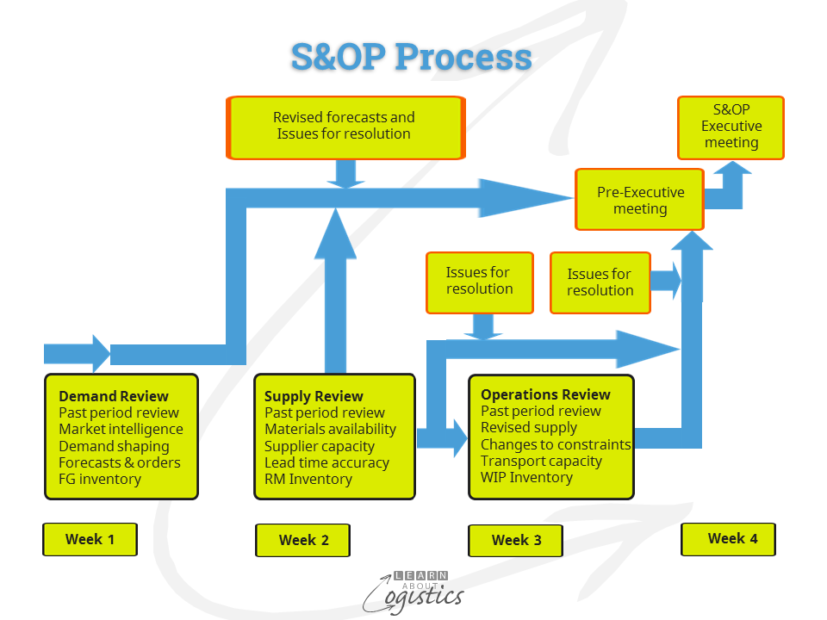

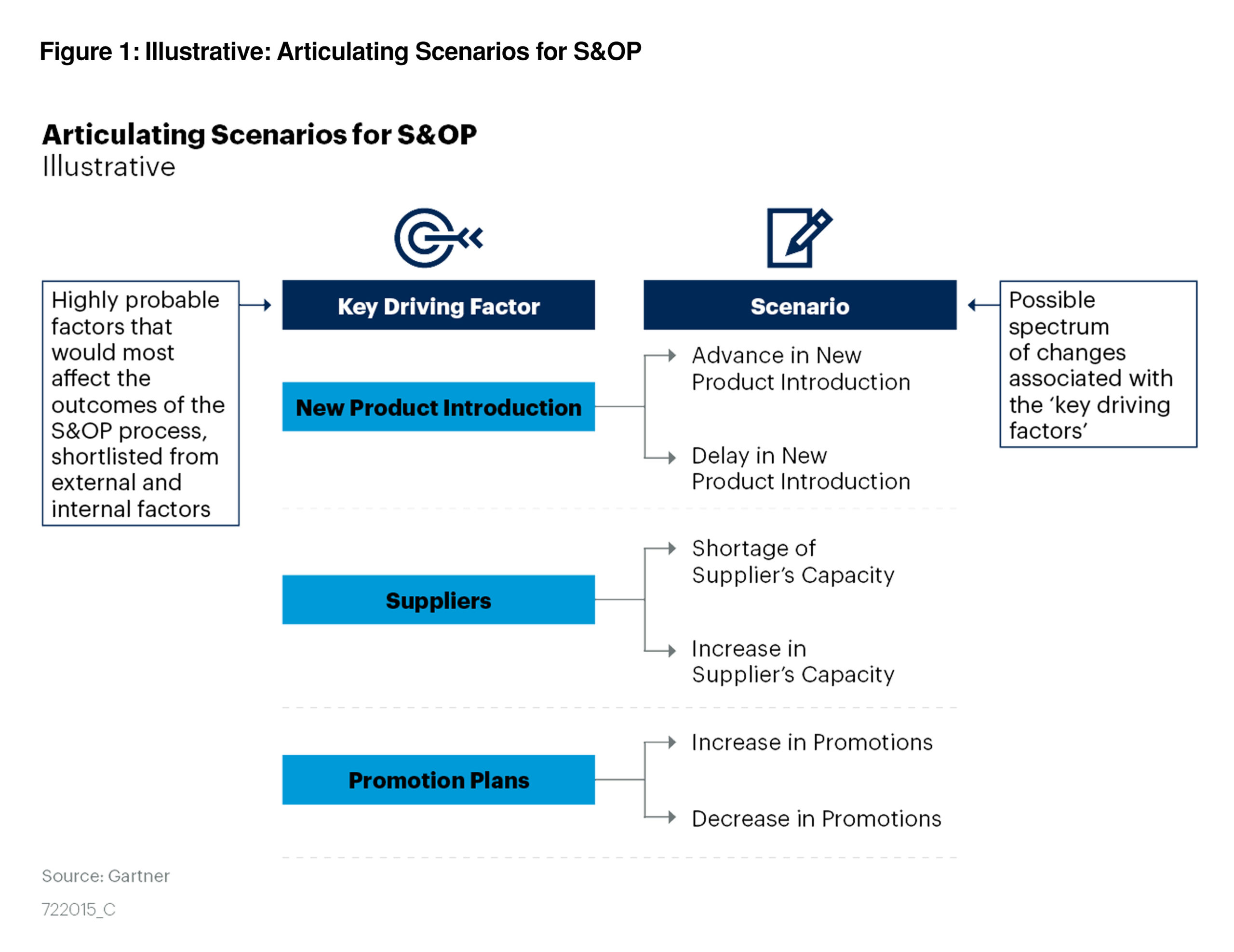

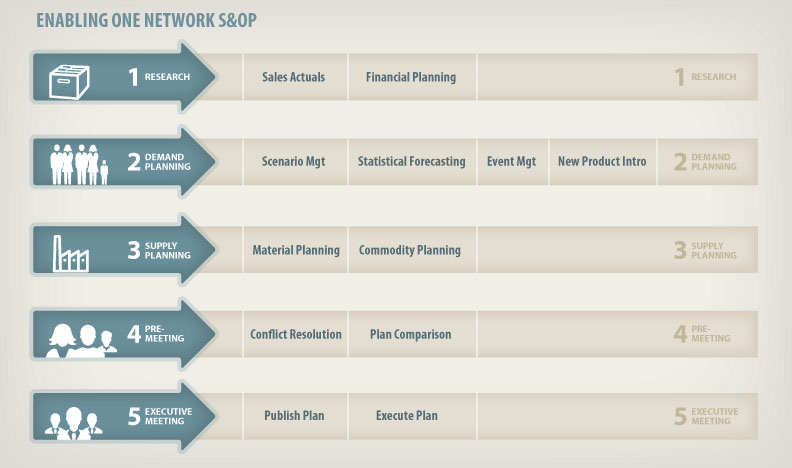

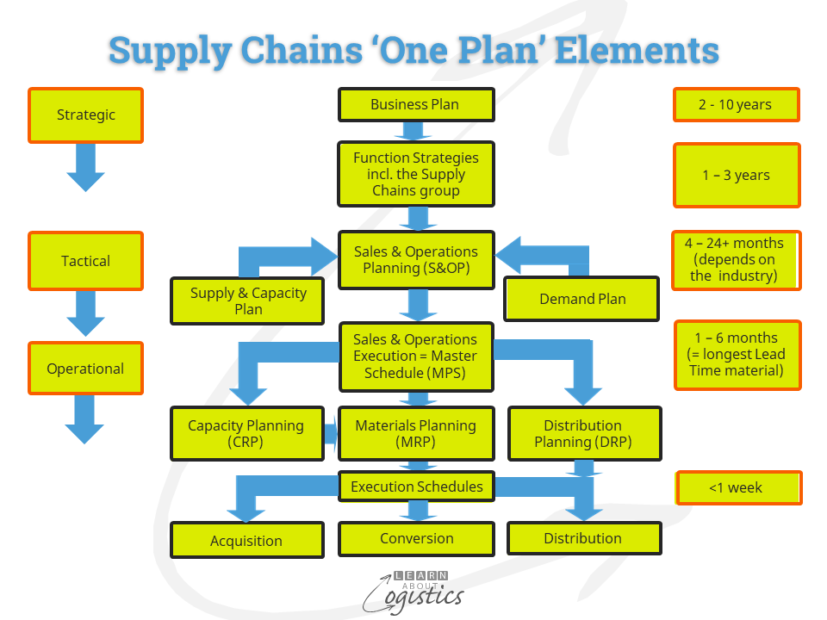

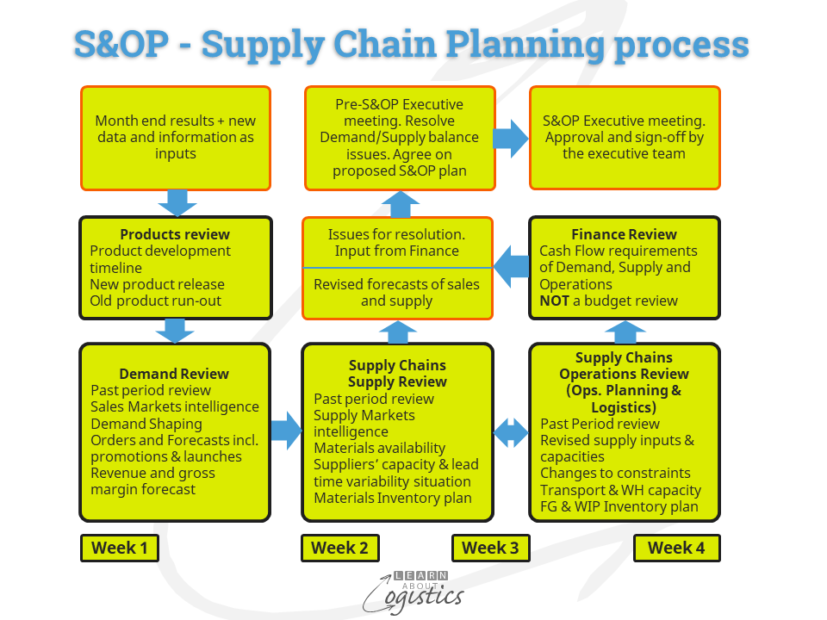

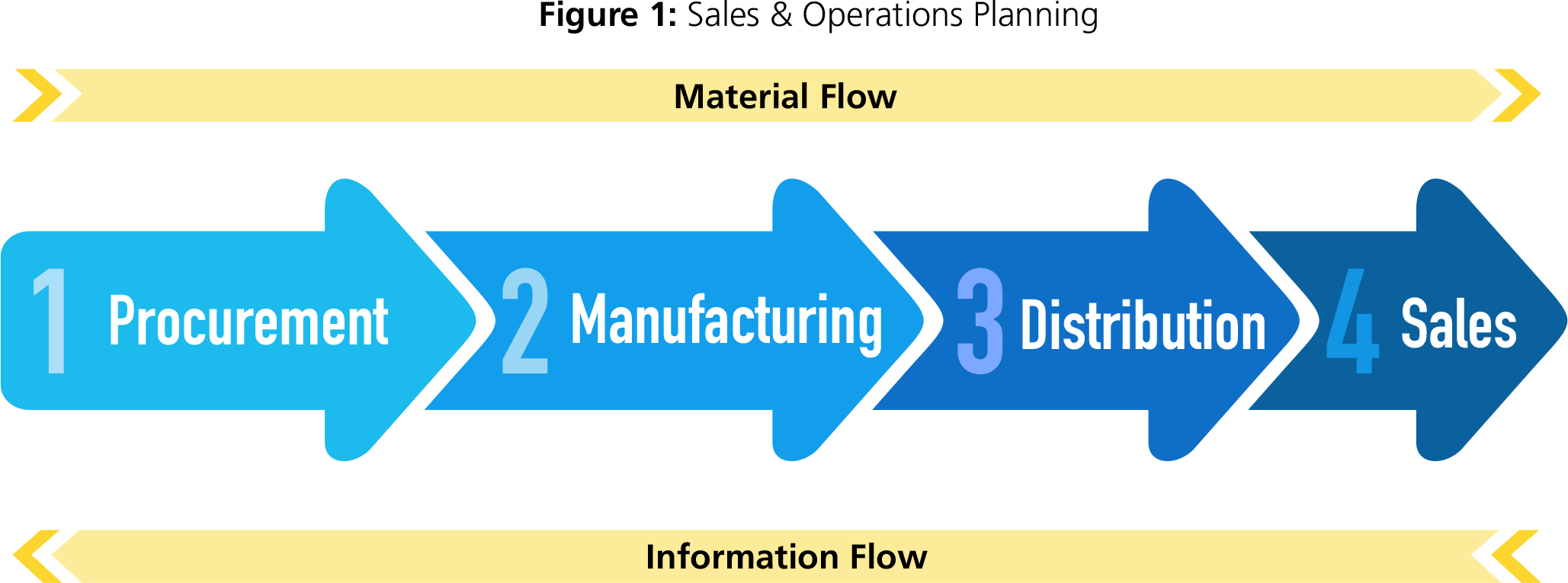

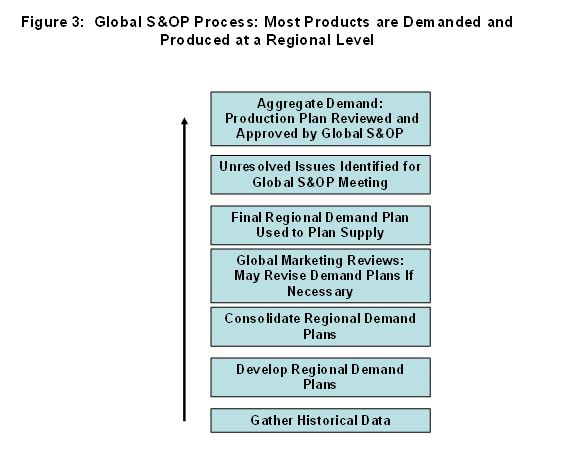

S&OP planning horizons may also vary by industry practice and business management planning horizons such as budgeting or new product research and development Budget process Fortyfive percent of respondents say they closely link the S&OP process to their financial budgets Strong financial integration should ideally be a part of the S&OP process The S&OP process frequently can be challenging to supply chain planning leaders It's crucial to business success, but rarely delivers on its full potential That's because it relies — more than any other supply chain process — on people from functions outside the supply chain recognizing and addressing the interdependencies between projects, product launches and S&OP gives management the ability to direct its business to achieve a sustainable competitive advantage The overall objective of S&OP is to arrive at a business "Game Plan" to help manage and allocate critical resources to meet the needs of the customer at the lowest cost S&OP is a fivestep process as illustrated in Figure 1

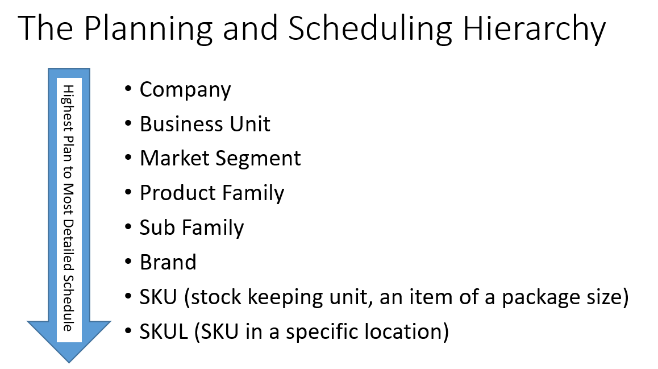

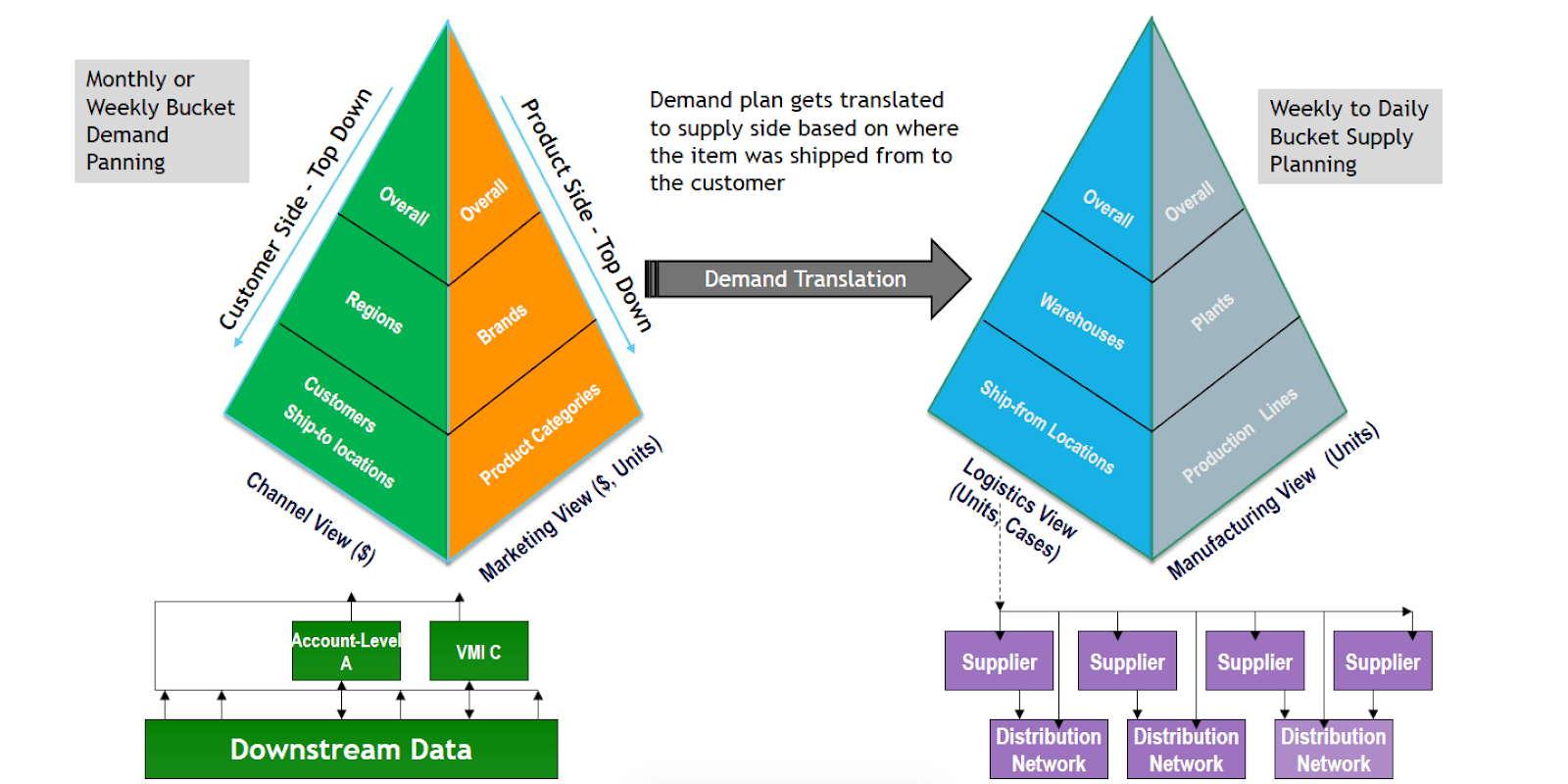

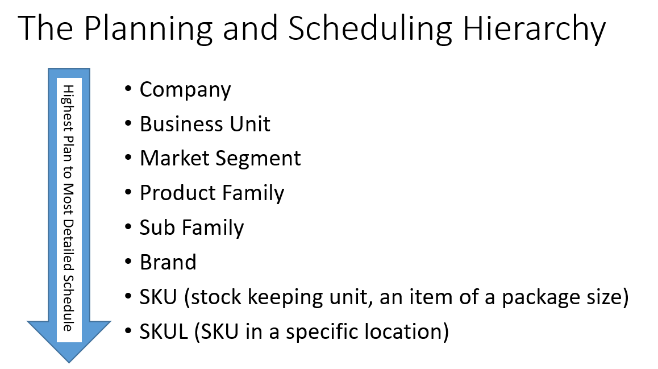

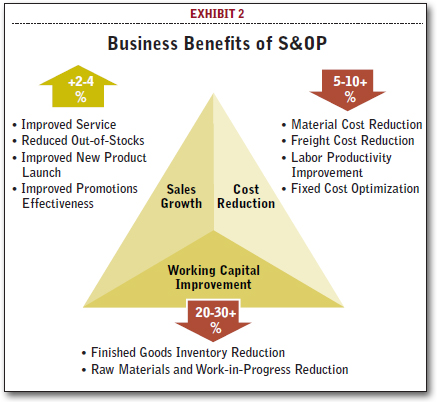

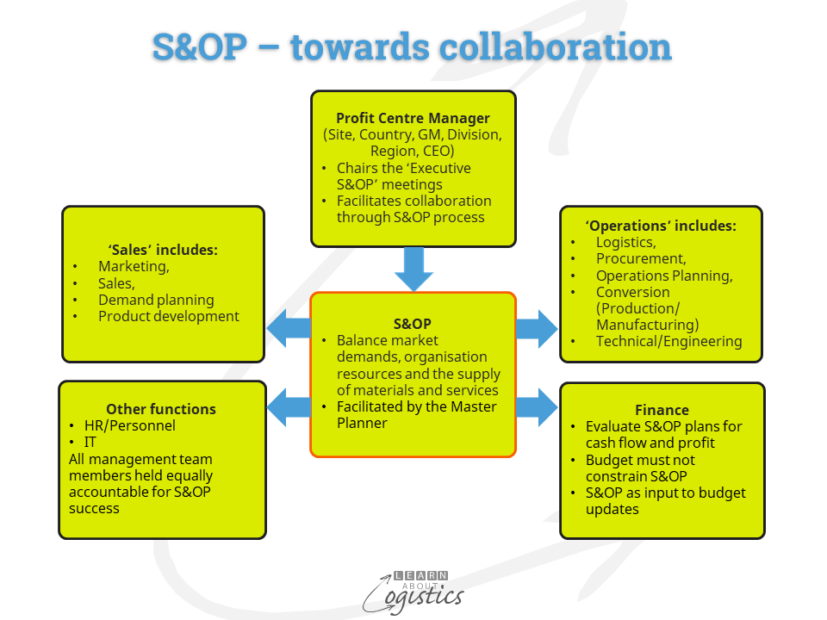

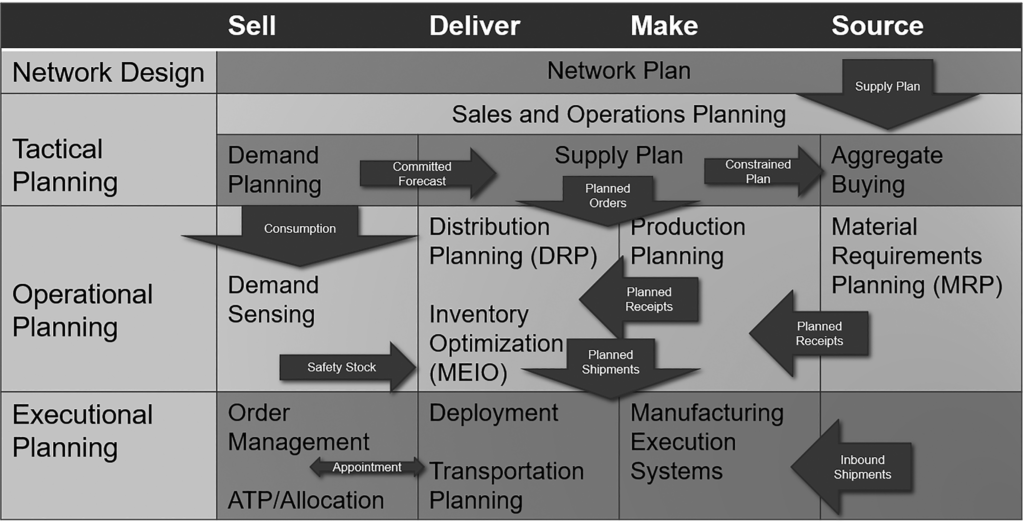

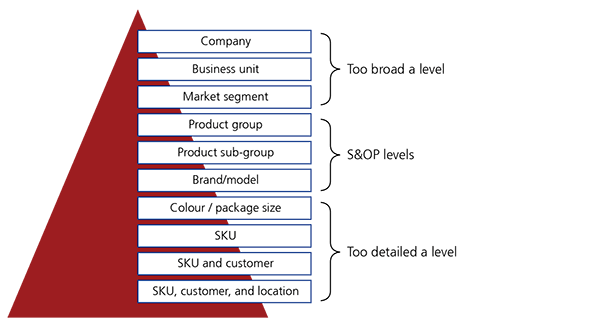

Aggregate Level Planning One of the primary benefits of S&OP is the planning structure Most forecasting processes generate forecasts only using an item's history In contrast, S&OP typically places that data in context, such as within a given market or customerTherefore S&OP is an input to budget updates, but should not be constrained by budgets A weekly and monthly operations meeting S&OP is a process focused on the whole Operational planning – Rolling twelve months, reviewed monthly Translates tactical plans into specific objectives and confirms activities and timings through shortterm plans and execution Goal of S&OP process The primary goal of the sales and operations planning process is to facilitate the flow of information between demand and supply

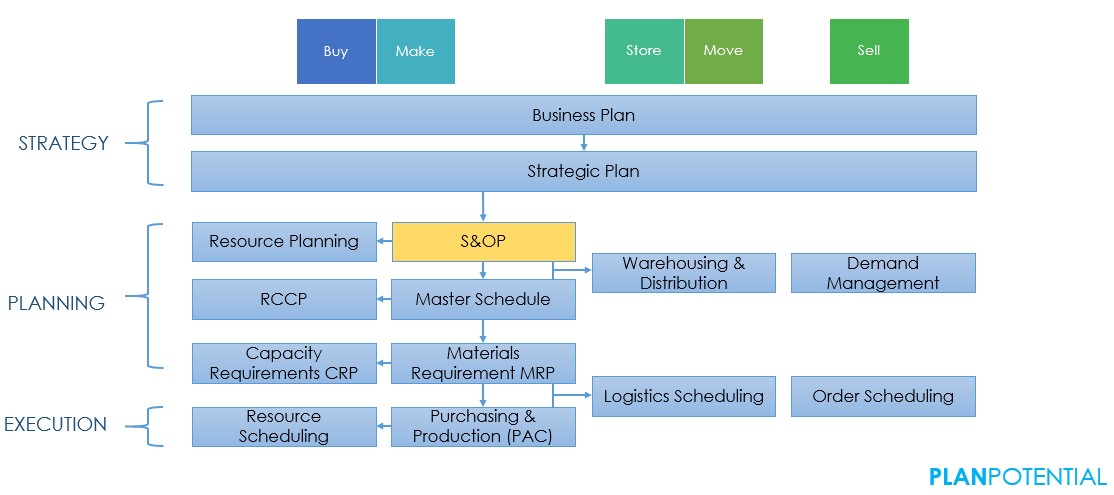

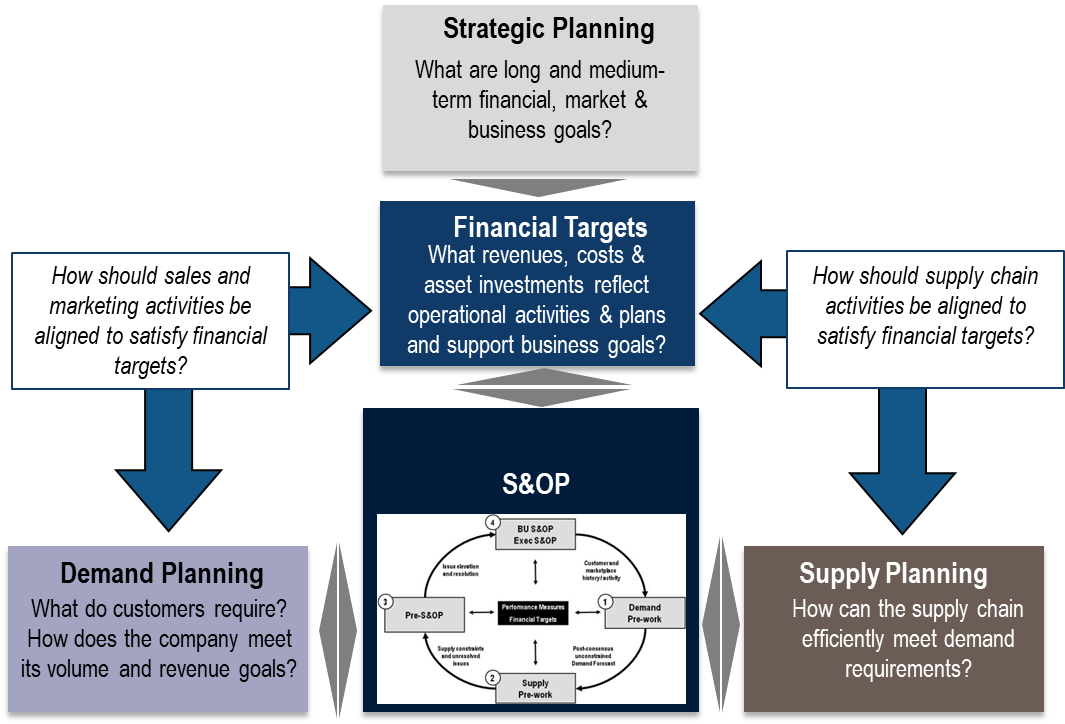

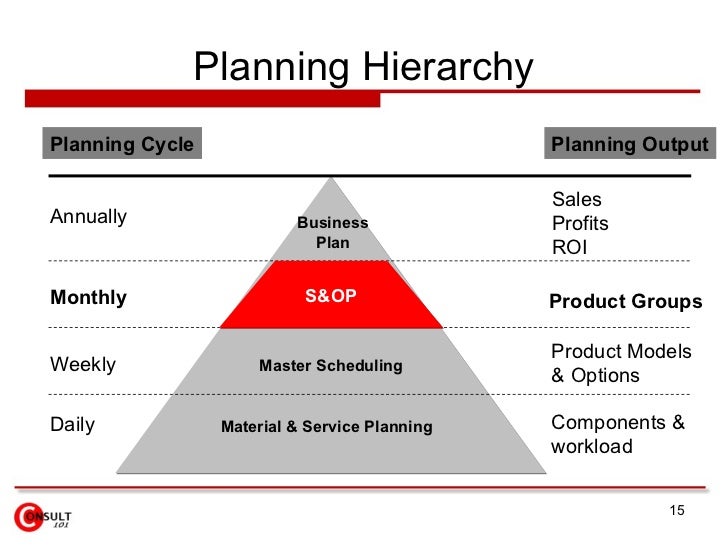

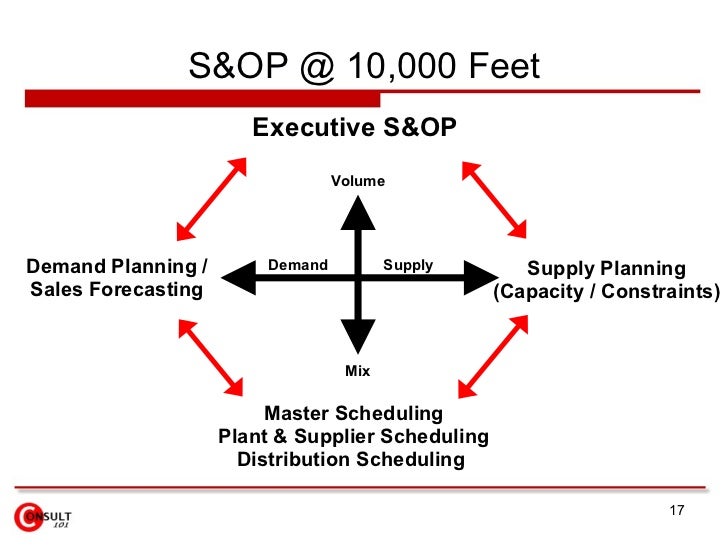

The following diagram shows where S&OP fits in the Business Enterprise Model It is a monthly planning process that deals with aggregate planning groups normally in monthly buckets Bookings, backlog, shipments, inventory, and supply are the key elements It is not a strategic planning process (this is higher level) nor is it a The segmentlevel S&OP process is the most important tactical planning process inside any business The purpose is to implement the business strategy in each market segment The gotomarket strategy comes to real life inside the S&OP process Each functional area has a specific role and is engaged in the overview of the whole businessWhile a formal definition of S&OP will follow, the process is carried out by what can best be described as a crossfunctional planning team comprised of midlevel managers and analysts (Stahl, 10;

Smoother Execution Through S Op Logistics Management

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Sales and operations planning (S&OP) is a business management process It involves all the functions of the business working together to manage the future supply chain as efficiently as possible It is intended to maximise revenue by planning ahead to ensure that customers orders are met as efficiently as possibleSales & Operations Planning (S&OP) The critical success factors Warehousing & distribution Customer Manufacturing Sourcing Assets & facilities Transportation Fast, effective process to assess the operations & financial impact and the best possible response v Single, organization wide demand & supply planning vi High costs savingsSales and operations planning (S&OP) is a process for better matching a manufacturer's supply with demand by having the sales department collaborate with operations to create a single production planThe broader goal is to align daily operations with corporate strategy

Improving Profitability With Sales Operations Planning Magellan Consulting Group

Ultimate Guide To Sales And Operations Planning S Op In 21

S&OP – Policies Policies Planning process & how demonstrated capacities by product family will be maintained and utilised Schedule of future meetings, attendees, & an agenda for a monthly review meeting Inventory, backorder, backlog plan, planning fences, service levels, new product intro, promotion, special offers etc Product familiesExecutive S&OP is a decisionmaking process that balances demand and supply at the aggregate level, aligns operational planning with financial planning, links strategic planning with daytoday sales and operational activities, and sets the tactical direction of the businessS&OP is gaining attention among organizations eager to implement powerful tactical management processes to help them succeed while navigating a rapidly changing business landscape Short for Sales and Operations Planning, S&OP is an integrated business management process that aligns all facets of an organization to their key market goals, synchronizing them and allowing the

S And Op Process Tutorial

Integrated Business Planning Ibp S Op Evolution Agile Innovation

The business plan S&OP provides a structure for planning to address mediumterm situations A budget review S&OP is based on current inputs concerning demand and supply;Sales and operations planning (S&OP) is an integrated planning process that aligns demand, supply, and financial planning and is managed as part of a company's master planning S&OP is designed and executed to support executive decisionmaking related to approving a feasible and profitable material and financial planThe Sales and Operations Planning Process (S&OP) is best defined as a planning process to ensure the business maintains sufficient inventory to meet customer demand The S&OP process typically operates on a monthly cadence, and includes a series of meetings that drive alignment between sales, marketing, and supply chain

Supply Planning Processes Options Analytics Oh My Plex Demandcaster

Sales Operations Planning Why Is S Op Important

S&OP is a structured monthly process that aligns all functional areas under a unified set of assumptions to enable and coordinate decision making It integrates demand, supply, operations, and financial planning into one game plan for business S&OP process drives success Communication between sales and supply chain helps the S&OP process Knowing each stakeholder's roles and responsibilities will drive the 6step Sales and Operations Planning process Additionally, the Sales and Operations Planning process empowers datadriven decisions It also holds all departments accountableAn Executive Whitepaper Successful Sales and Operations Planning in 5 Steps LOGILITY VOYAGER SOLUTIONS wwwlogilitycom 2 Executive Overview The Sales and Operations Planning (S&OP)1 process is well known and understood in the world of supply chain management

Smoother Execution Through S Op Logistics Management

Sales And Operations Planning S Op Monthly Process Conceptdraw Biggerplate

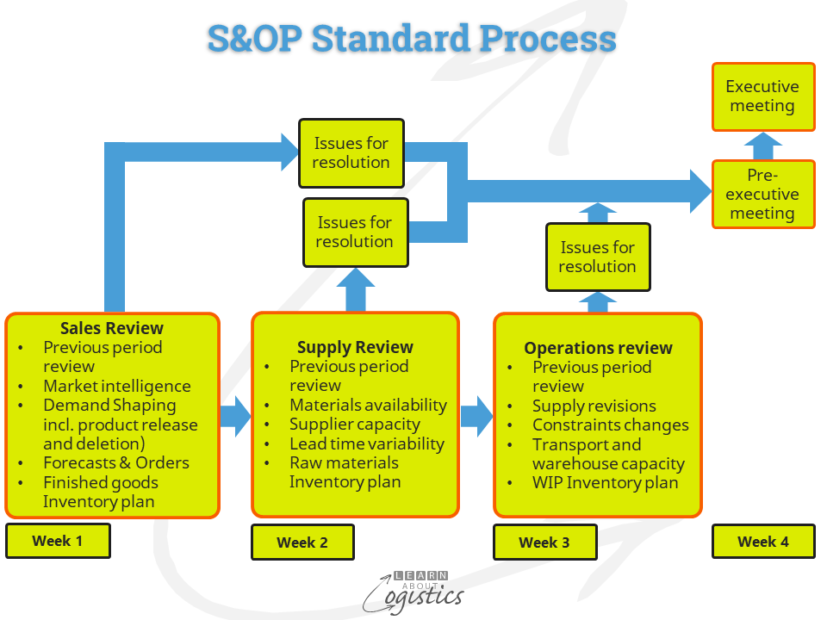

S&OP process is guided by output from strategic planning and, in turn, drives daily operations This makes S&OP the "linchpin" planning process, connecting strategy to execution Obviously, this is a critical planning process for any business The accuracy of S&OP plans invariably determines how well a company achieves its• Organization follows S&OP process/plan • Further case analyses and interviews • Results in a nutshell • Many companies are trying (have tried), but only few succeed(ed) • Oftentimes process was implemented but not executed, ie back to business as usual 9 Results S&OP impact and success factors (Pibernik & Rexhausen, 12) 10 Demand Planning has the first six workdays of the monthly S&OP process to report KPIs, revise baseline and/or event forecasts, and review results with key internal partners Demand Planning finalizes the demand plan, and hands it over to Supply Planning on day seven

Scm Awareness S Op Process Planpotential

Involving Execution Managers With Sales And Operations Planning Supply Chain 24 7

S&OP is an enterprise wide business planning process that can only be effective and sustainable when it is supported by the right mindset and behaviours Individuals and teams with a superior mindset will increase S&OP effectiveness and are proven to perform better and show increased wellbeingExecutive Summary This report traces the evolution of Sales & Operations Planning (S&OP) from its inception in the late 1980's, where the primary objective was a medium to longterm stable production plan, to the 21st century, where several successful businesses are using it as a dynamic business performance managementprocess tracking their progress against strategic directionWagner, Ullrich, & Transchel, 13)

Sales And Operations Planning Wikiwand

Using Retail S Op To Make The Holiday Season Smoother And More Profitable Multichannel Merchant

The integration of S&OP and inventory optimization can create a greatly enhanced process known as sales, inventory & operations planning (SI&OP) While SI&OP is most commonly used as a term synonymous with S&OP, its process entails utilizing inventory optimization techniques instead of traditional inventory planning processes S&OP – Process Mapping (As~Is / To~Be) 55 S&OP Process Improvement Framework Continuous Improvement Identify Best Practices As~Is Analyse & Evaluate To~Be Implement Business Process Reengineer Business Process Improvement Approaches 56Normally, S&OP is considered as a monthly process with crossfunctional activity, driven by a single plan with designated participants to develop a consensus supply plan aligned to firm's

S Op Integration With Other Plans Source Adapted From Operations Download Scientific Diagram

Fixing An Overly Complicated Sales And Operational Planning Process Supply And Demand Chain Executive

Common Steps in the S&OP Process The S&OP process can be broken down into six essential steps data gathering and forecasting, demand planning, production planning, preSOP meeting, executive S&OP meeting, and the S&OP strategy implementation Let's take a look at each of these steps in greater detail 1What is Sales & Operations Planning (S&OP)?S&OP, or sales & operations planning, is a monthly integrated business management process that empowers leadership to focus on key supply chain drivers, including sales, marketing, demand management, production, inventory management, and new product introduction

What Is One Plan S Op Arkieva

Sitmi Science Industrial Technology And Management Intelligence S Op Sales And Operations Planning Process Flow Simple And Quick Explanation Of Each Steps Facebook

The first step for the supply chain planning leader is to identify the S&OE content in the S&OP process and move it to a separate agenda As a rule of thumb, anything that covers the nearterm horizon, commonly 0 to 3 months, is S&OE It deals with all the issues stemming from actual demand and supply — the reality of supply chain that isImplementing Sales and Operations Planning (S&OP) In our knowledge article What is S&OP?, we explained what sales and operations planning (S&OP) is and its many advantagesTo sum up, S&OP is the creation of a unified, consensusbased business plan that enables organizations to control inventory costs while vastly improving service levels Whether the S&OP software offers integrated planning or tackles only one step of the process, the analytical and predictive power it affords is crucial to any business looking to grow Include S&OP in the Strategic Plan It is important for management to incorporate the S&OP planning process into the overall strategic planning of the organization

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

1

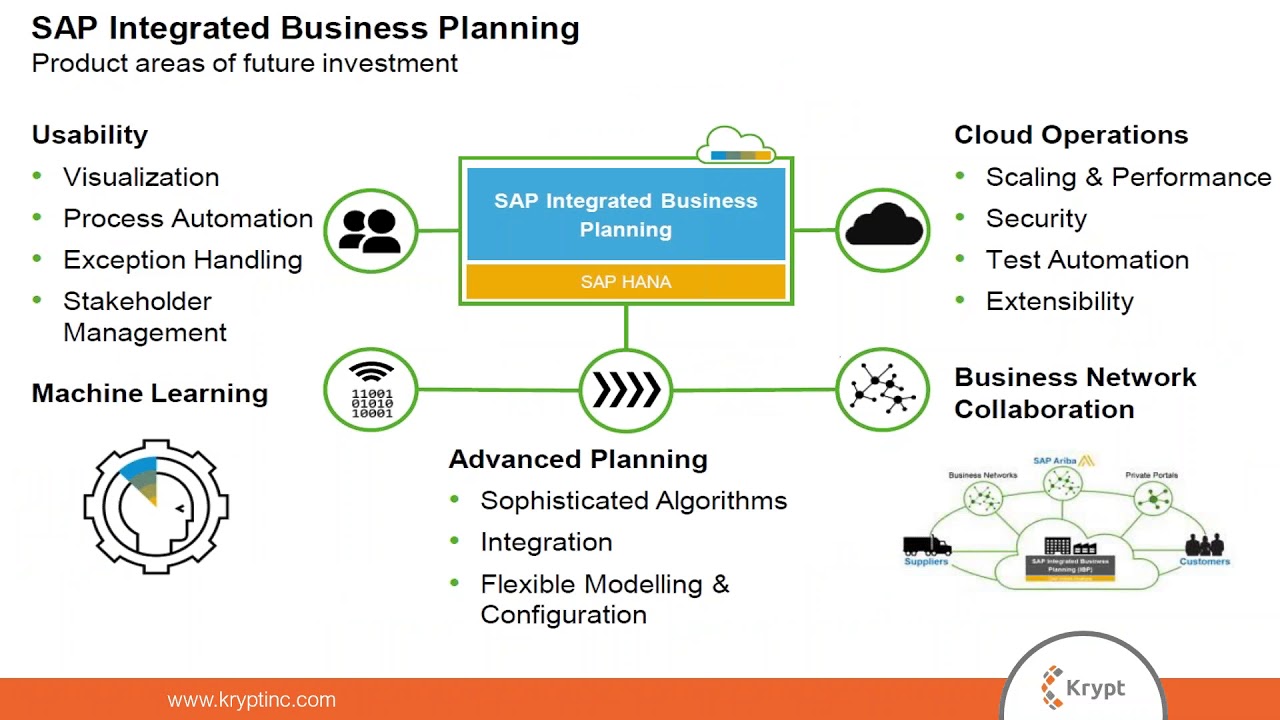

Module 1 Assignment 2 Sales & Operations Planning Process Overview In this assignment you will create a deliverable to describe the Sales & Operation (S&OP) Planning Process You may choose the type of deliverable that you will create Specific instructions are included below Instructions In Module 1, we learned about the Sales & Operation Planning (S&OP) processThe S&OP process plan is optimized to financial outcome vs heuristics whereas most S&OP processes are merely centered on matching demand and supply while taking into account manufacturing and supply chain constraints More advanced approaches require users to enter unit costs by facility as an input into supply chain planning, which then seeksThe S&OP planning process should always be built on a realistic foundation, as the base line determines the trustworthiness of the S&OP plan That is why the operational plan should integrate towards IBP for S&OP (preferably via HANA Cloud Integration, HCI) HCI allows you to integrate data from your legacy system to IBP for S&OP applying

Sales And Operations Planning S Op Logistiikan Maailma

Oracle Demantra Sales And Operations Planning User Guide

S&OP journey on tools Partially in SAP Manual Excel SAP ECC & SCM 40 Live SAP ECC (60) & SCM (70) upgrade Future –create process efficiency 06 08 10 12 14 16 SAP project launch Fully in SAP 5 S&OP enablers SAP Journey New future technologies –S&OP on Sales and Operations Planning (S&OP) Sales and operations planning (S&OP) is a business management process where leadership and executive teams meet to ensure each business function is aligned to balance supply and demand S&OP requires crossorganizational collaboration to create detailed forecasts for predicted sales

S Op More Important For Planning New Era Supply Chains Learn About Logistics

The Sales And Operations Planning Process In The Context Of Various Download Scientific Diagram

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

S Op Process

Successful Change Management Adds Value To Your S Op Process Implement Consulting Group

1

How To Make The S Op Process More Robust Demand Planning

Introducing Sap Ibp S Op Processes Webinar Youtube

The Fully Integrated S Op In Supply Chain Planning Context Download Scientific Diagram

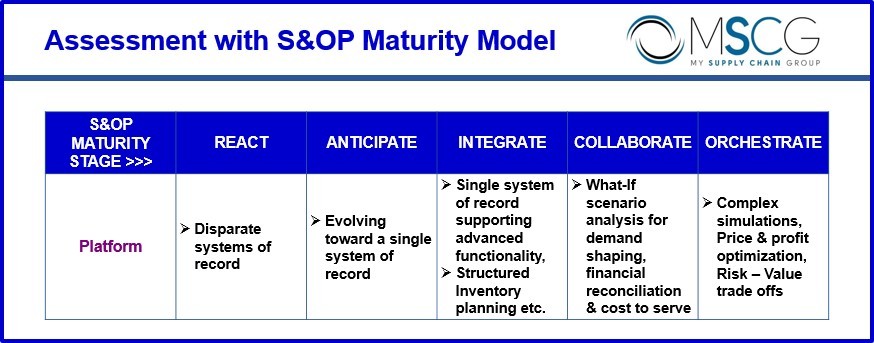

Road Map Of Integrated Business Planning For Supply Chain Part Ii The 5 Ps Of S Op Maturity My Supply Chain Group

Sales And Operations Planning Process Self Assessment

S Op Process Impacts Excess Finished Goods And Operational Efficiency Hawkeyeconsultingadvisors

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

1

S Oe Where The Rubber Meets The Road The Pointy End Of S Op

Sales And Operations Planning S Op 101 Smartsheet

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

The S Op Journey Beyond The Supply Demand Match Organization And Ownership For The Demand Planning Process Aberdeen Strategy Research

What Is S Op How S Op Works Demand Planning Com

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

S Op Process

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

What Is Sales And Operations Planning S Op Plex Demandcaster

Sales And Operations Planning A Project Manager S Guide Asana

Implement The S Op Process For Supply Chain Success Learn About Logistics

Sales And Operations Planning S Op Transform Your Business

Sales And Operations Planning Business Forecasting Taruna Nagpal

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

5 Proven Tips For Improving Your Sales And Operations Planning

Sales And Operations Planning Explorescm

Who Should Own Sales And Operations Planning I Kinaxis

What Is S Op The Origins Use And Value Of Sales Operations Planning

Leveraging Scenario Planning For S Op Decision Support

1

Integrating The S Op Process Go With The Flow Online Sales Guide Tips

The S Op And The 3 Different Levels Of General Planning Based On Apics Download Scientific Diagram

Sales Operations Planning Scpi

Sales Role In Sales And Operation Planning Demand Planning The Sales Process Blog

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

Chapter 14 Aggregate Sales And Operations Planning Lecture

Sales And Operations Planning S Op

Supply Chain News What We See In S Op

2

Sales And Operations Planning In Manufacturing Manage Collaboration Across The Entire Organization Tompkins Solutions

S Op Sales And Operations Planning And Sco

S Op Effectiveness Recommendations To Make The Leap Supply Chain Shaman

Sales Operations Planning Consulting Supply Velocity

Sales And Operations Planning S Op Logistiikan Maailma

Sales Operations Planning A Proven Business Process Learn About Logistics

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

S Op More Important For Planning New Era Supply Chains Learn About Logistics

What Is S Op How S Op Works Demand Planning Com

Sales Operations Planning Engagement Model Tvo Maine Pointe

Sap Integrated Business Planning Ibp Sales And Operations Planning 18 Sap Blogs

S Op Software Sales And Operations Planning Qad Dynasys

What Is S Op Or Sales Operation Planning Sales And Operation Planning Definition And Steps

S Op Is The Hub Of Supply Chains In Your Business Learn About Logistics

Sales And Operations Planning A Project Manager S Guide Asana

Supply Chain Graphic Of The Week The S Op Process

Sales And Operations Planning Report Do You Get Surprises

What Are The Basic Elements Of The S Op Process Quora

Ready To Upgrade Your S Op Process For Industry 4 0

Integrating Suppliers In Sales Operations Planning Whitepaper On S Op Process Gep

Sales And Operations Planning Relex Solutions

Dp Vs S Op Process Flow

Sales And Operations Planning Relex Solutions

The Lost Link To Make Strategy Work Sales Operations Planning S Op Strategok By Javier Go Sales And Operations Planning Business Architecture Strategies

Gartner Blog Network

A Paradigm Lost It S Not All About Changes In Demand

What Is S Op How S Op Works Demand Planning Com

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

A Comprehensive Overview Of Sales And Operations Planning S Op

What S Holding The S Op Process Back Part Two Establishing A Business Efficiency Planning Process That Works Chainalytics

S Op Process

What Is S Op How S Op Works Demand Planning Com

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning Relex Solutions

S Op And S Oe A Symbiotic Relationship

Getting To Grips With Sales And Operational Planning Bloor Research

Sales And Operations Planning Myths Part 3 Supply Chain 24 7

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales And Operations Planning

0 件のコメント:

コメントを投稿